Machine cleaning

WELFARE FLUID

Complete service and equipment for your machines, including the option of ecological waste disposalMachine cleaning

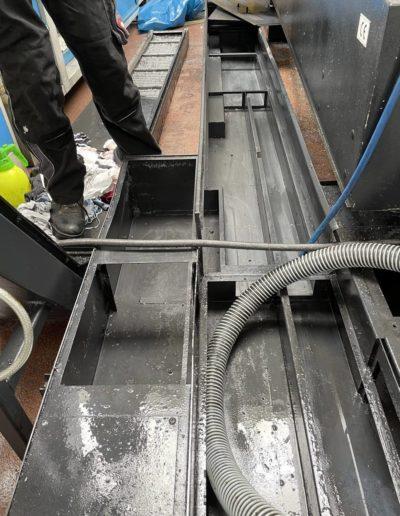

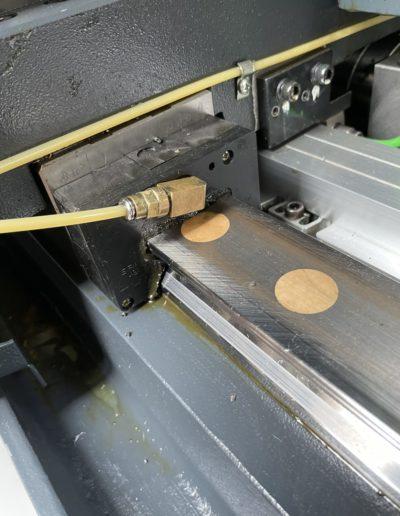

For cleaning, we use the most modern MKR SF 500 cleaning equipment with a specially adapted vacuum cleaner with a volume of 500 l, which can completely vacuum the entire tank of the machine. The built-in high-pressure pump then cleans the inside of the machine using filtered fluid. And with the help of technical preparations, we fine-tune the machine to the maximum.

We can clean all kinds of metalworking fluids, water from degreasing baths, cutting fluids, hydraulic oils and many other fluids and oils. We have been cleaning machines for over 15 years, we use proven cleaning and disinfecting agents and we are constantly improving our services. As we are engineers, we understand all brands of machines.

It reduces the risk of unplanned machine servicing

Increases the cleanliness of the environment

Reduces the risk of skin problems for machine operators

Complete vacuuming of the machine tank

Quick cleaning - minimal downtime of the machine from production

Questions and answers

FAQ

What makes our solution better?

What types of fluids can you clean?

We can clean all kinds of metal working fluids, water from degreasing baths, cutting oils, hydraulic oils and many other liquids and oils.